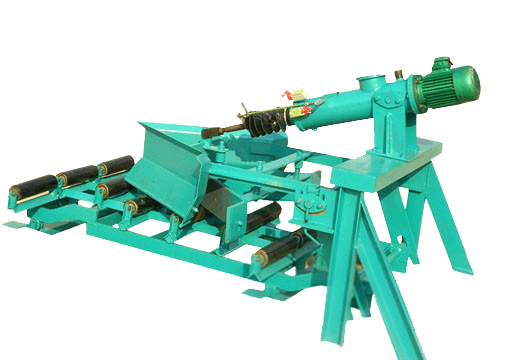

working principle:

Plow-type unloader uses electro-hydraulic push rod as the power source. During operation, the drive rod is extended through the push rod to drive the frame forward to complete the machine head fall and support the flat roller group to make the working surface of the tape straight. The lower edge of the head is tightly attached to the tape surface. The material on the tape is written into the bucket and sent to the required place. After the discharge is completed, the electro-hydraulic push rod is activated to retract the drive rod, which drives the frame to retreat and lift the ploughshare. The idler roller group changes from parallel to trough shape to allow the material to pass smoothly. (For the operating principle of the electro-hydraulic putter, see the putter section)

Features:

1. The main and auxiliary plow heads are used, the plow is made of wear-resistant cast iron, the head is shaped at a small angle, and the tail is arc-shaped, so that when plowing coal, the plow is more close to the rubber surface and the discharge is smoother and cleaner.

2. The plough head can be fine-tuned up and down, and the angle can also be adjusted by the pull rod, so it is very convenient to adjust downwards during installation or after the plough is worn.

3. The whole machine has the advantages of high intensity and no jitter.

4. It can be used for remote centralized control and on-site operation, which is convenient for the entire system to achieve centralized control and program control.

5. Suitable material size: 0 ~ 200mm. 6. Applicable belt speed: 0.8 ~ 3m.